When a hydraulic hose bursts, it’s important to understand the cause of the problem in order to ensure it doesn’t happen again. It’s also important to consider what substance or liquid the hose contains, and to evacuate the area as quickly as possible if any potentially dangerous substances are exposed.

Hose failure due to bursting can happen, however in many cases hoses can be fixed after bursting. The solution depends entirely on what has caused the problem in the first place.

This post will guide you through the most common causes of hydraulic hoses bursting and how to identifying symptoms for prevention. For more detailed information on hydraulic hose failure and the main reasons behind this, please read our previous post.

1. The Fitting Has Blown Off the Hose

The cause of this problem is most commonly because the hose was not injected far enough into the shell of the fitting during original assembly. Depending on the type of hose and it’s fitting, the fitting may have grips in the shell, all of these grips are needed to hold the fitting onto the hose. These grips, the last one in particular, are pivotal when it comes to applying the full holding strength needed to secure the hose in the fitting.

Solution: In this instance, the hose assembly will need to be replaced. Ensure that the correct assembly of the hose is carried out, in order to avoid this from happening in future.

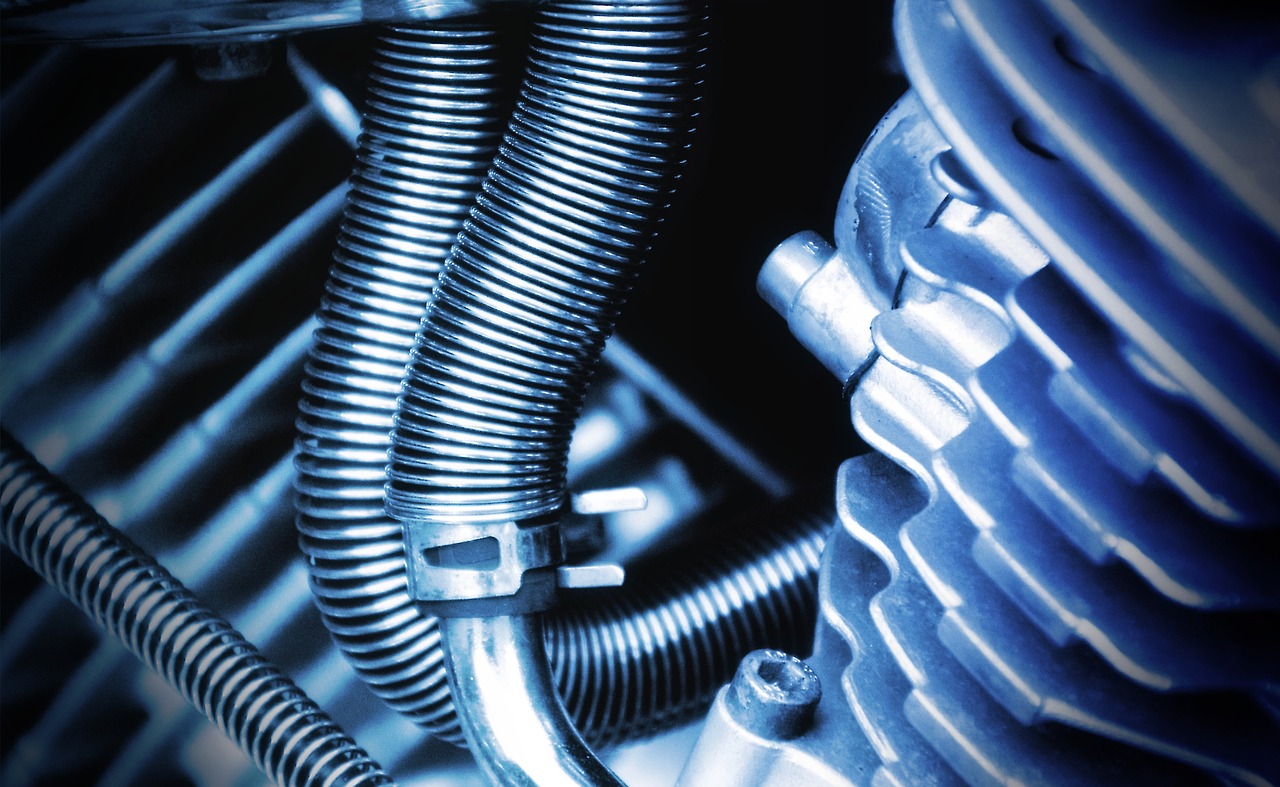

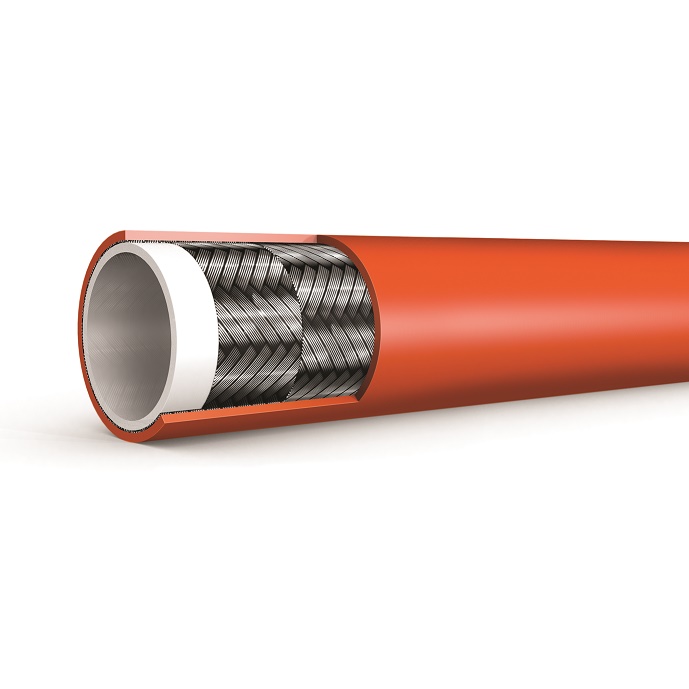

2. The Wire Reinforcement has Failed

After a hose burst happens, the braid along the outside of the hose will be visibly broken. Furthermore, there will be minimalised outward deflection of wire in the relative area. When this occurs, it is clear that the hose can no longer work effectively.

Solution: Assess the application and then replace the entire hose assembly.

3. Torn Cover and Reinforcement Wires Damage

When a hose bursts and leaves the cover either torn or deteriorated, the reinforcement wires can also be affected and may be rubbed, broken or corroded. This outcome could be a result of excessive rubbing of the hose against external objects, or possibly as a result of the wrong size clamp being used.

Solution: The hose assembly needs to be replaced and the use of a hose guard is recommended . Ensure that the correct size clamps are being used in order to prevent this happening again.

4. The Outside of a Bend has Burst and the Hose Remains Bent

Although the hose remains bent, you will find it still remains flexible, when a burst such as this occurs. It’s likely that there will be broken wires in the area of failure around the outside bend of the hose. If the hose is flattened in the area of the bend it could restrict the flow of substance through it; this could be caused by a bend occurring to close to the fitting or due to the minimum bend radius being exceeded during use.

Solution: The hose assembly requires replacement and it will then need to be re-routed to increase the bend radius.

In order to prevent any form of hose burst or hose failure occurring, we recommend the implementation of regular ongoing inspections and a regular maintenance program. The regularity of these inspections may differ from business to business, depending on the types of hoses and their uses. Nevertheless, any form of maintenance programme will help to prevent bursting occurring in the future and is necessary in order for you to keep your hoses in good condition.