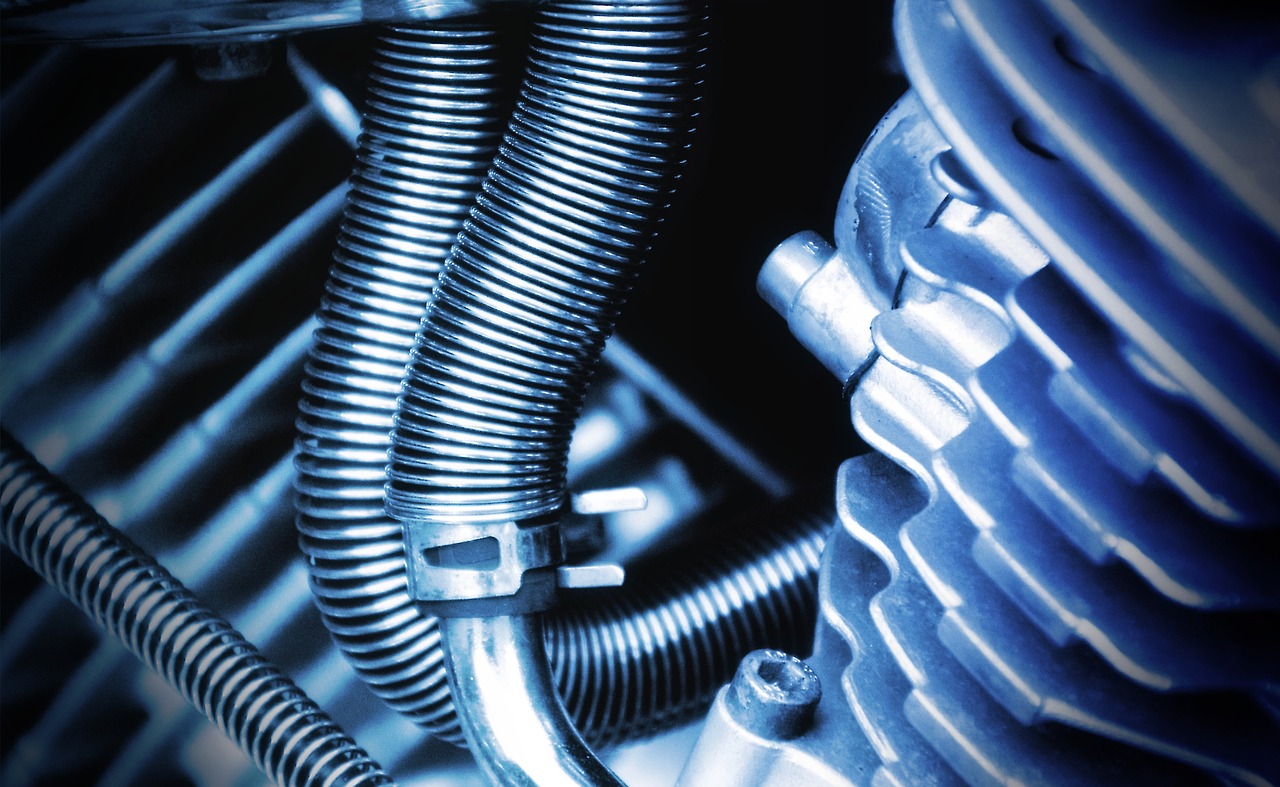

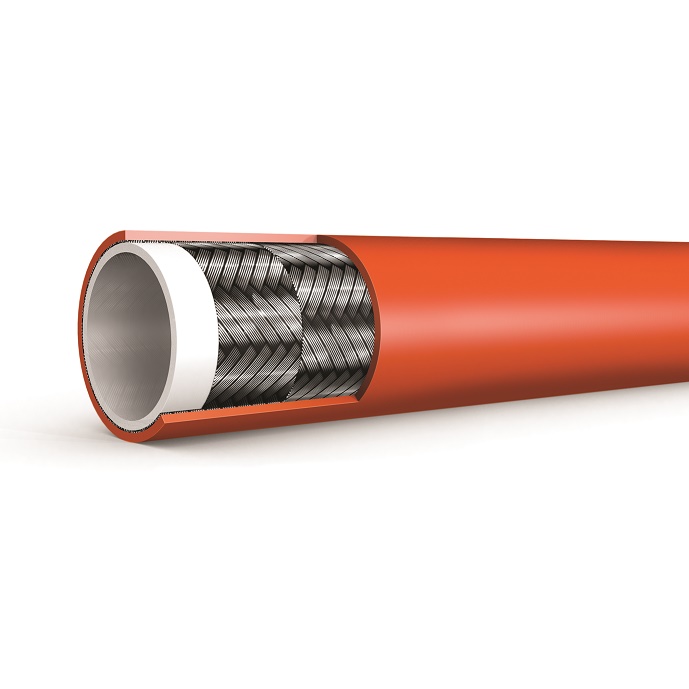

Hydraulic hoses are extremely useful for a wide range of industries, and they can be used to transfer liquids and gases from one location to another. They are a vital component for hydraulic systems and machinery, and their high pressures and toxic contents can mean that hose damage or failure can be catastrophic.

What are the risks associated with hydraulic hose failure?

When hydraulic hose fails, it can quickly become a danger to nearby employees and the environment. If the hose contains a flammable liquid, then a leakage could cause a fire if it is exposed to an ignition source. This has potentially lethal consequences to those nearby.

Fluid burns are also a risk (depending on the contents of the hose). In fact, high pressures mean that toxic hydraulic fluid can even be injected into the body, which can cause serious health issues such as tissue damage.

Other risks include slipping hazards, as hydraulic oil will cause surfaces to lose their grip until they are properly cleaned. Costs can also be monumental for the business, due to unplanned downtime and the need to clean and dispose of leaking hydraulic fluid.

What can cause hydraulic hose to fail?

To prevent accidents from occurring, it is essential to know the main causes of hydraulic hose failure.

Improper assembly

Improper assembly

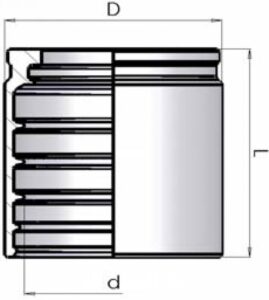

Improper assembly is one of the most common reasons why a hydraulic hose will become damaged or fail. For example, if the hose is not fully inserted into a fitting, it can cause the fitting to fly off and cause injury to someone nearby. It can also result in leaks that are costly to fix and clean, and the fluid inside the system may also become contaminated as a result.

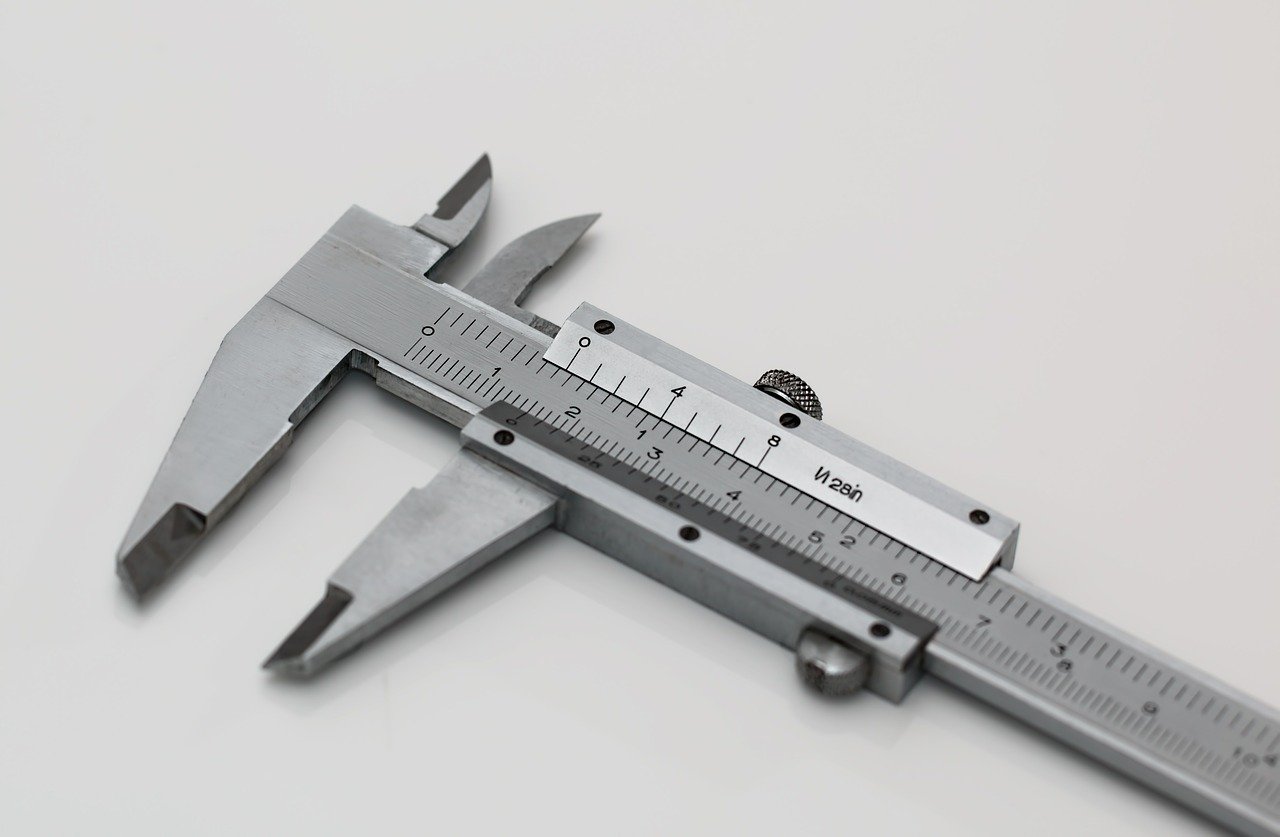

Always ensure that you follow assembly guidelines and ensure that you use the correct fittings for your hose size and application.

- Incorrect application

Exposing a hydraulic hose to temperatures outside of its specifications can cause the polymers to harden or stiffen, resulting in cracking as the hose bends. If high temperatures have caused your hose to become damaged, then you will be required to replace it with a model that is better suited to the heat levels produced.

In some cases, damage is caused by using a fluid that is incompatible with the type of hydraulic hose that you choose, causing the inner tube to decay or swell.

If you are unsure about which size and type of hose assembly is best suited to your requirements, contact your chosen supplier for more information. At Hose Shop, we are experts in supplying the correct types of hose to our customers. Speak to our team today for no-obligation advice.

- Lack of maintenance

Failure to check and maintain your hose assembly can be costly for your business and dangerous for your staff. Kinks and splits as well as missing brackets and clamps are all potential issues, and these can be identified and fixed during routine inspections. You will also be able to visually check for abrasion, which can be caused by the hose rubbing against machinery as it contracts and expands.

Ensure that the system is turned off prior to inspections and create a standardised process for checking your hose.

To replace your hydraulic hose or to enquire about the best type of hose for your requirements, contact our expert team today.