Learn about Hydraulic Hoses with HoseShop

One of the most important types of Industrial Hose that we supply here at HoseShop is Hydraulic Hose. Hydraulic hoses are used on many applications for transmitting pressurised fluids to machinery where power is required. In simple terms, without hydraulic hoses, then a lot of vital machinery wouldn’t work as they are a core component of them!

A hydraulic hose tends to be made from synthetic material such as rubber which makes them durable and resistant to things such as the weather, rot and friction damage. Furthermore these hoses tend to be reinforced in order to protect them from from damage that can be sustained during mechanical processes. The most common fluid that is found and transmitted within a hydraulic hose is oil, however water is often commonly used. Both fluids have their own particular benefits and it depends on the requirements of the hose as to which is the best.

Regardless of which fluid you use, a huge benefit of either system is that only one source of pressure is required, even on systems with several functions. The flexibility of these hoses – even with them being reinforced, means that they can get round corners or obstacles, or be fed through suitable holes in walls and other structures easily – without the fear that they may rupture.

Hydraulic hoses are mostly used machinery to provide linear or rotary motion.

Differences between fluids in hydraulic hoses

The main advantage of using oil in hydraulic hose, is that it is self lubricating. Pressures can go as high as 400 bars (6000psi) The down side is that it cannot be used where there is a fire risk. Also any oil spillage should be considered for environmental health, and safety reasons.

The benefit of using water is that it is cheap, no fire risk, corrosion, to steel parts to be considered, minimal contamination on water spillage. The downside is that pressures can only go up to approximately 200 bars (3000 PSI) due to the lack of lubricity in the fluid. But to work at these pressures means that special materials have to be used hence more expensive prod ucts.

ucts.

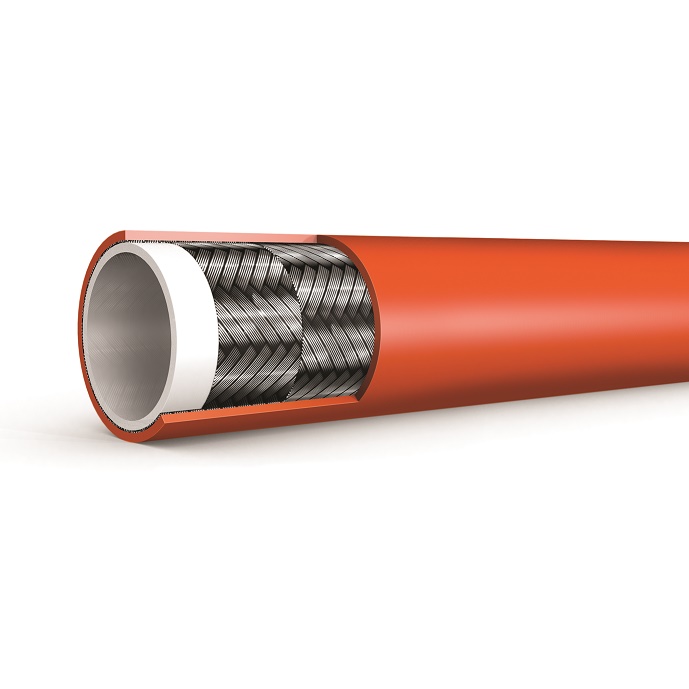

Hydraulic hose tends to be made from three layers. These can vary in terms of what the components are made from but as a rule hydraulic hoses tend to have the following make up:

– Inner Tube – this is the internal part of the hose. It needs to be compatible with the type of fluid that it will be transferring, so as to avoid corrosion. This also means that it needs to be able to handle the stress and pressure that is needed for motion and force as well as allowing free flow.

– Reinforcement – this is a layer that surrounds the inner tube; made from wire which is either coiled or braided. This both supports and protects the inner tube, in order to avoid tears and damage

– Outer Layer- The outer layer of the hydraulic hose is made of rigid materials which keep the internal contents safe and avoids the elements having any effect on the workings.

Typical examples where hydraulic hoses are used are: excavators that we see on our streets. Refuse vehicles, road sweepers, agricultural machinery, industrial processes, marine applications / steel works, food production. Anywhere where power is required you tend to find hydraulic hoses.

We are experts when it comes to hydraulic hoses, get in touch with HoseShop today and see what we can do to help you with your requirements.