Effective hose maintenance is the key to a longer lifespan, without a maintenance program, hose damage occurs much more rapidly. Learning how to look after your hose is important but also knowing the signs of when a hose is already damaged is vital too.

Fittings and other components for hoses sadly don’t last forever, even when an appropriate maintenance programme is established, eventually they will have to be repaired or replaced. Knowing the tell-tale symptoms of a damaged hose will save you a lot of time and allow you to repair and replace parts as quickly as possible. So, how do you determine whether you have a damaged hose or not?

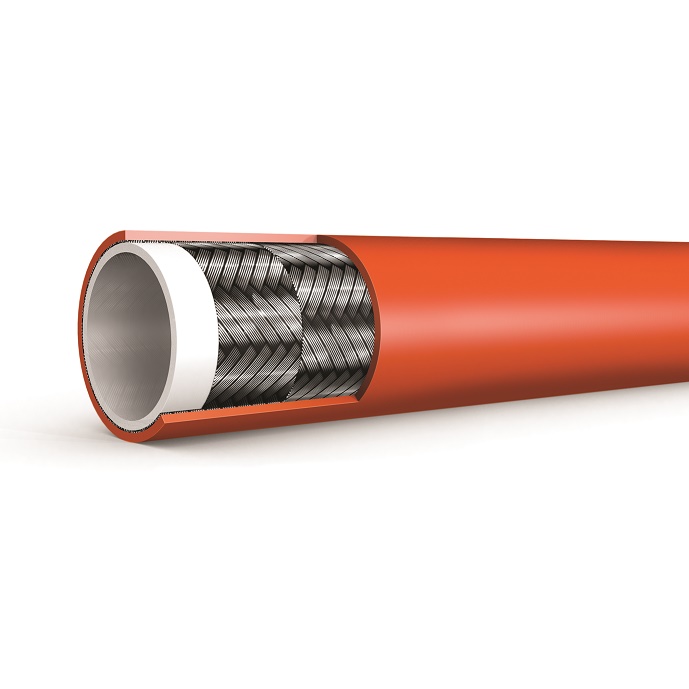

1. You Need to Visually Inspect the Hose

As good general practice, you should inspect your hose and the fittings regularly, be sure to keep an eye out for the following signs;

- Slippage on the hose fitting.

- Check the cover for signs of cracking, cutting or any exposure of reinforcements.

- Stiffness, hardness, heat cracks and damages or a charred hose.

- Corroded or cracked fittings.

- Leaks around the fitting and through the hose.

- Twisted, flattened, crushed or severely kinked hose.

- Soft, degraded, blistered or a very loose cover.

If you feel any of the above have occurred, it is highly likely the hose is damaged and will need repairing or replacing, depending on the type of damage and severity.

2. Monitor all Hose Assembly Components

These accompanying components to hoses are very important when it comes to determining how damaged a hose is overall. Be sure to look out for;

- Excess build-up of dirt and bacteria.

- Worn clamps, guards or shields.

- Monitor the system fluid level and the fluid type used.

Some items may need tightening, repairing or correcting if you spot any of these symptoms. It may seem time consuming at first, however, it could save you having to pay out for a full hydraulic hose repair or replacement in the long run so it’s well worth it.

3. Replacements will be Required in Intervals

Hose fittings, assemblies and elastomeric seals need to be inspected at regular intervals for replacement. These components in particular will need to be replaced from time to time to ensure the hose continues to work properly and safely. Elastomeric seals in particular will eventually age and deteriorate, due to their exposure to thermal cycling and compression.

Therefore, it’s a good idea to create replacement intervals where these inspections are carried out to check on components. These components should be examined against government or industry recommendations.

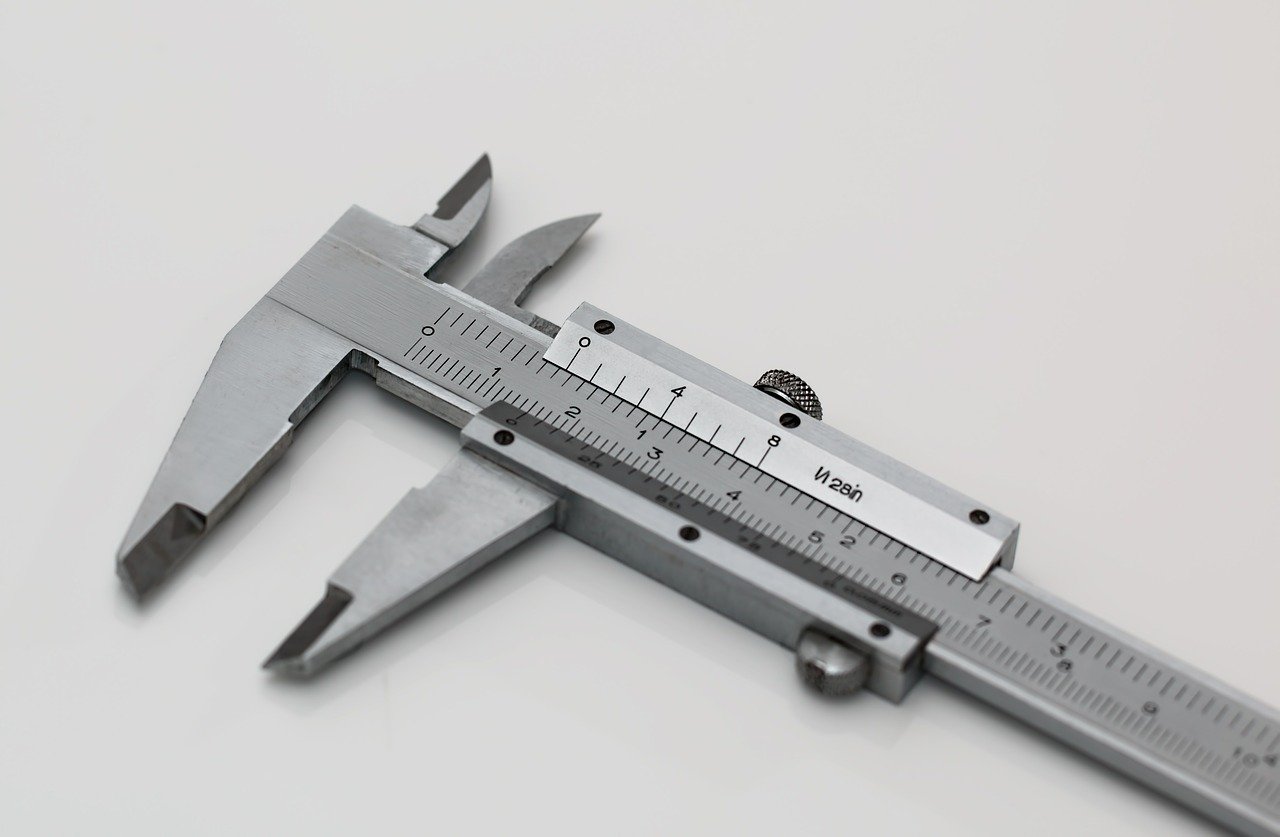

4. Physically Test it Out

If you want to monitor the performance of your hose to check for damage, operate the hose as normal and check for possible leaks or failures in the hose.

Monitor the pressure when testing the hose, ensure the peak pressures and maximum working pressure isn’t being exceeded by the hose during performance. When testing be sure the tests are carried out in a safe and non-hazardous environment.

5. The Difference Between Damage and Failure

To learn about the most common types of hose failure to better distinguish between hose damage and failure, please read our previous post. Overall, failure of a hose can be caused by a number of different reasons including improper maintenance, wear and tear and even misuse. Once a hose has failed, it sadly won’t be able to be repaired, it will need to be completely replaced.

If you require any more information please contact our expert team. In addition, if you need any replacement parts or components, please check out our shop containing both industrial hoses and hose accessories.