Hose installation can often seem like a specialist art, but knowing the best practices can help to make the process as painless as possible. There’s a reasonable amount to cover in terms of installation itself, but there’s also a few neat little tips and a couple of safety points to bear in mind, too.

Get Your Spacing Right

When installing a hose, it’s worth assessing the space before you get properly started. If you’re putting in a small metal hose inside your home, you’ll need to work out how it will fit in the space effectively. Remember, this is more than just the length of the hose. You’ll need to make sure the hose is slightly longer than you initially need because when the pressurised water flows, the hose’s diameter increases to deal with that pressure. Because of this, there needs a little bit of slack when installed, otherwise when it widens it will be too short between the industrial hose fittings.

If no extra hose length is given, the hose will swell when the liquid passes through it and it could break off from the fitting. This can lead to serious leaking and water damage which might not be immediately accessible to rectify.

Cut out the Corners

In a similar vein, a hose should be installed with as soft a bend as possible. In other words, a hose should not have anything in it that could even remotely resemble a corner. A bend should be rounded and shallow. This reduces the friction on the inside of the hose, and allows the liquid inside to pass through with as little resistance as possible, maximising efficiency.

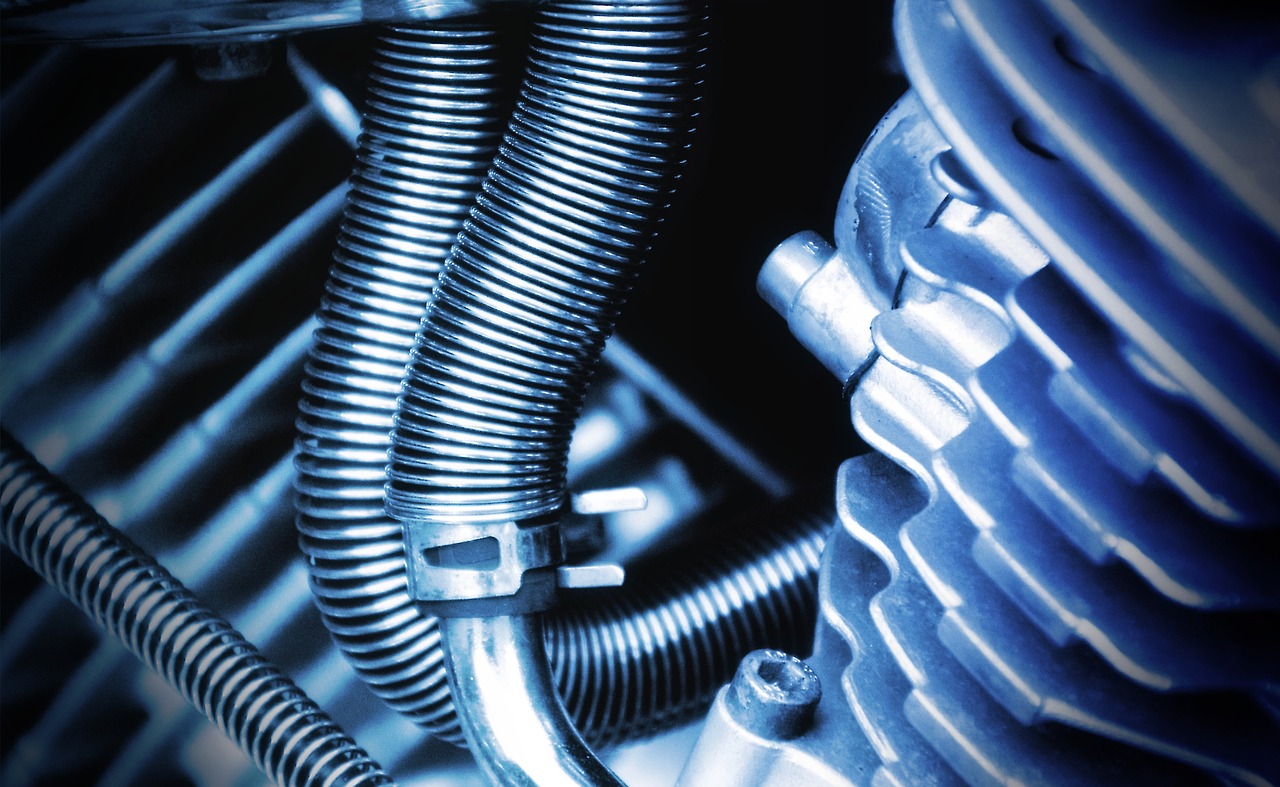

Metal tubing is stronger than hose when dealing with just strain, but the flexibility of reinforced hose is a massive plus-point. Hose also has the added benefit of being specially designed for pressurised fluid, and hoses such as a suction hose can be used while moving. You should be using hose for this advantage, otherwise it wouldn’t be fit to do its job as it’s meant to.

Don’t Get Your Hoses in a Twist

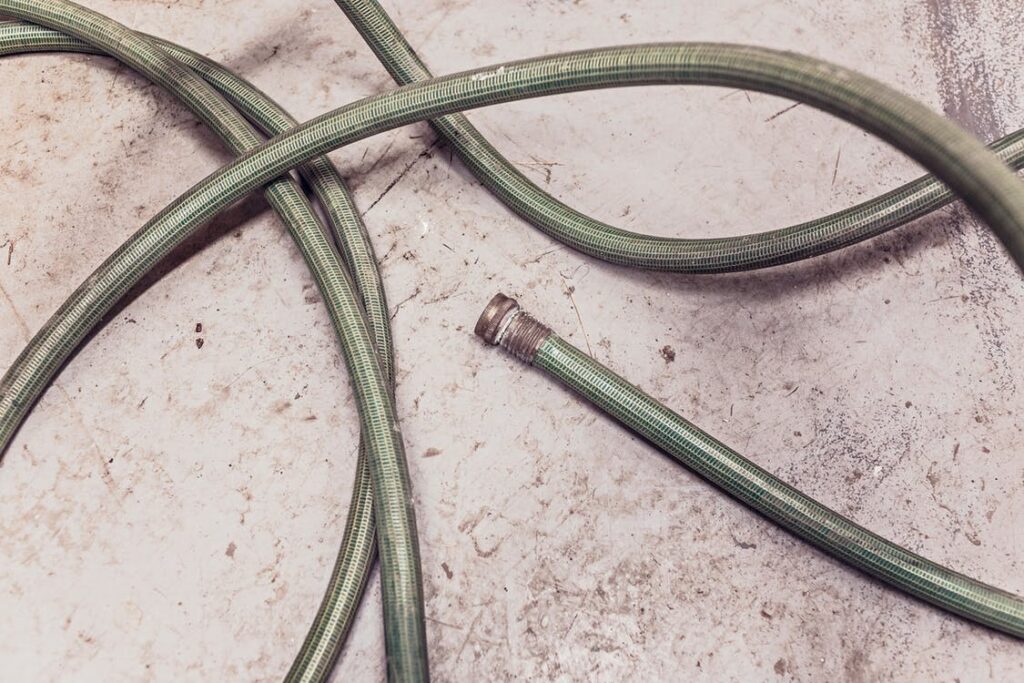

While you’re installing your hose, you should also make sure that you avoid what’s known as ‘hose twist’. It’s fairly self-explanatory but, to clarify, it’s when the hose is twisted so that the inner bore is not one continuous plane. This generally comes about when the hose is fitted to go through two dimensions of movement – up/down as well as left/right, for instance.

To detect it, look at any printed writing on the outside of the hose. If it’s anything but straight, then your hose is twisted. Unlock it from the fittings and adjust. It’s important to avoid hose twist because it decreases the pressure of the transported liquid due to the extra friction in the hose. Essentially, a twisted hose is a less efficient hose.

Play it Safe

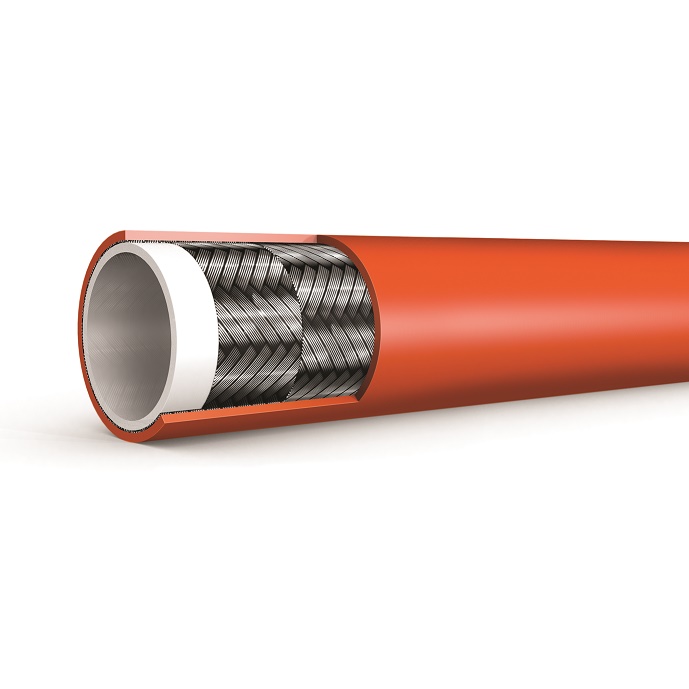

Hydraulic hoses are a crucial piece of equipment for many industries because of their reliability and durability. To achieve this, they are reinforced with wire braiding. For safety reasons, it’s important to know that because this wire is made from metal – often steel. This means that it is an electrical conductor.

It’s unlikely to happen, but it’s worth knowing that due to the friction and pressure of transferring fluid in the hose, there can be a build up of static electricity. In extreme cases, this can ignite nearby flammable solutions (fabric, oil, etc) and cause serious fire damage. Make sure that there are no flammable solutions in the area immediately around your hydraulic hose.