What can cause hydraulic hose failure?

Used predominantly as industrial hoses, there are many different factors that can lead to a hydraulic hose failure. Below we have highlighted 5 important factors you need to be aware of.

- Abrasion

Rough treatment of your hydraulic hose such as pulling, crushing, and scratching its covering on surrounding surfaces etc. can seriously reduce the hose life and cause failure. Therefore, before use it is advisable to look for any indications of past abuse that may have weakened the hydraulic hose. If you find any tears, damaged reinforcement, or soft spots, replacement of the hose is necessary.

In order to avoid abrasion, you should consider the least hazardous path for the hose and invest in protective sleeves or spiral hose guards. Additionally, be mindful to avoid kinking and pulling when operating the hose.

- Extremes in Temperatures

Due to high operating temperatures and cold periods where the hose is inactive, the extremes in temperature can cause the hose to age rapidly, thus making them more vulnerable to deteriorate. In order to try and prevent this deterioration, you must wherever possible protect the hydraulic hose from exposure to temperatures outside their operating range. One way to do this, is to choose a route for the hose that is away from primary heat sources as this will reduce exposure to high temperatures; alternately, in extreme cases you could use a heat shield to protect the hose.

- Pressure Fluctuations

Similar to extremes in temperatures, severe pressure fluctuations above the normal operating pressure can often lead to premature hose failure. Therefore, it is essential to properly couple both high and low pressure components to maintain the performance and lifespan of the hose.

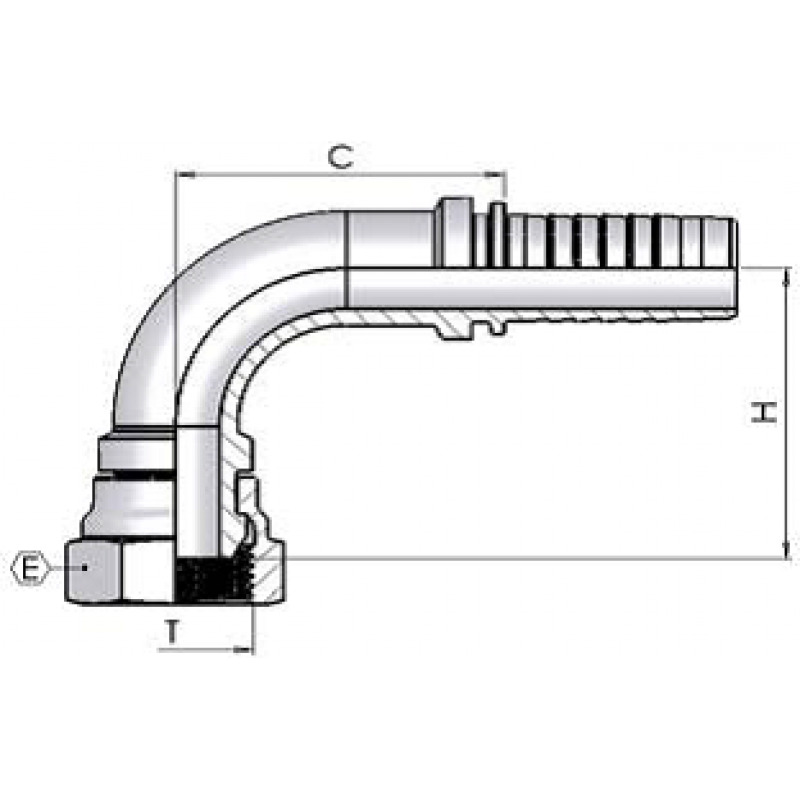

- Bending and Twisting

To a certain extent hydraulic hoses are designed to bend, however twisting is another matter. Even a fairly small twist beyond the natural radius of the hose can cause splitting and failure of the hose. Therefore extra precautions need to be put in place when clamping or installing the hose as this is how twisting can occur. Additionally, to prolong the life of your hydraulic hose, it is essential to avoid bending the hose in more than one dimensional plane as this can also damage the hose.

- Improper storage

A key factor that often causes premature failure in hydraulic hoses is improper storage. It has been proven that hoses which are neatly stored above ground are less likely to be damaged by environmental factors or industrial equipment and personnel. Therefore, in order to prolong your hose life, you should store the hose above ground, away from direct sunlight, and in a clean, dry environment. Not only will good storage extend the life and performance of your hydraulic hose, you will also be creating a safer, more constructive working environment.

At HoseShop we understand that a failure of a hydraulic hose can be catastrophic, therefore the precautionary measures above are designed to help minimise the risk of a failure occurring. When it comes to industrial hoses, here at HoseShop we have extensive knowledge of the hose industry and its products, so if you have any questions or need advice, get in touch our range of hose protection and safety is available to browse online!

Learn more about how to prevent hydraulic hose failure.